Manual Clutch for Predator 212⁚ A Comprehensive Guide

This guide will provide you with a comprehensive overview of manual clutches for Predator 212 engines, focusing on the benefits, types, installation, and maintenance of these powerful upgrades. We’ll delve into the popular 3D Motorsport manual clutch, detailing its features and installation process. Whether you’re a seasoned kart racer or a novice looking to enhance your Predator 212 powered vehicle, this guide will equip you with the knowledge to make informed decisions and unleash the full potential of your engine.

Introduction

The Predator 212 engine, renowned for its power and affordability, is a popular choice for go-karts, mini bikes, and other small-scale vehicles. While the engine’s centrifugal clutch provides an automatic transmission system, many enthusiasts opt for a manual clutch for enhanced control and performance. A manual clutch allows the driver to engage and disengage power to the wheels at will, offering a more responsive and engaging driving experience. This transition from automatic to manual operation unlocks a world of possibilities for those seeking to refine their driving skills and optimize the performance of their Predator 212-powered machine.

This comprehensive guide delves into the world of manual clutches for Predator 212 engines, exploring their benefits, types, installation procedures, and maintenance tips. We’ll unpack the key aspects of these clutches, providing you with the knowledge to make informed decisions and enhance your understanding of this popular engine modification. Whether you’re looking to improve your kart’s acceleration, achieve smoother gear changes, or simply enjoy a more engaging driving experience, this guide will serve as your roadmap to the world of manual clutches for Predator 212 engines.

The Benefits of a Manual Clutch

Installing a manual clutch on your Predator 212 engine offers a range of advantages over the standard centrifugal clutch, enhancing both performance and driving enjoyment. One of the most significant benefits is the ability to precisely control power delivery. With a manual clutch, you can seamlessly engage and disengage power, enabling smoother acceleration, improved traction, and enhanced control during cornering and braking. This level of precision is particularly valuable in racing applications, where every fraction of a second counts.

Beyond performance benefits, manual clutches provide a more engaging driving experience. The act of shifting gears manually adds an element of skill and control, making the driving process more interactive and rewarding. It allows drivers to fine-tune their driving style, optimizing performance based on track conditions and personal preferences. Furthermore, the ability to disengage the clutch provides a safety advantage, enabling drivers to quickly stop the engine or prevent stalling in situations where the engine may be overloaded.

In summary, a manual clutch is a valuable upgrade for Predator 212 engine users seeking enhanced control, improved performance, and a more engaging driving experience. It provides the driver with the ability to precisely manage power delivery, optimize acceleration and braking, and enjoy a more responsive and rewarding driving experience.

Types of Manual Clutches

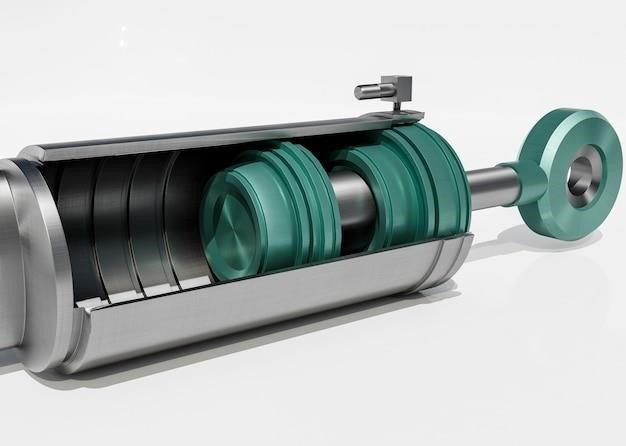

When it comes to manual clutches for Predator 212 engines, there are a few key types to consider, each with its own advantages and drawbacks. The most common type is the cable-operated clutch, which is typically found on go-karts and mini bikes. These clutches use a cable to engage and disengage the clutch, making them relatively simple to install and operate. They offer a good balance of performance and ease of use, making them a popular choice for many enthusiasts.

Another type of manual clutch is the hydraulic clutch. These clutches use hydraulic pressure to engage and disengage the clutch, providing a smoother and more precise feel compared to cable-operated clutches. Hydraulic clutches are often found on higher-performance karts and mini bikes, where the demand for precise control is greater. However, they can be more complex to install and require regular maintenance of the hydraulic system.

Finally, there are centrifugal clutches, which are typically used as automatic clutches on Predator 212 engines. These clutches engage and disengage based on engine speed, eliminating the need for a manual shift lever. While convenient, centrifugal clutches lack the control and precision of manual clutches, making them less desirable for performance-oriented applications. When choosing a manual clutch for your Predator 212 engine, carefully consider the type that best suits your needs and budget.

The 3D Motorsport Manual Clutch

The 3DME clutch, a patent-pending innovation by 3D Motorsport Engineering, stands out as a highly regarded option for Predator 212 engine enthusiasts. This cable-operated bolt-on unit is designed for straightforward installation, replacing a typical centrifugal clutch in a matter of minutes. Its user-friendly design and ease of installation make it a popular choice among kart racers and mini bike enthusiasts seeking a performance upgrade.

The 3DME clutch is renowned for its robust construction and high-quality components, ensuring reliable performance even under demanding conditions. It is specifically tailored to the Predator 212 engine, providing a perfect fit and seamless integration. Its compatibility with various kart and mini bike setups makes it a versatile choice for diverse applications.

The 3DME clutch offers several advantages over centrifugal clutches. It provides greater control and precision over engine power delivery, enabling drivers to fine-tune their performance and maximize acceleration. The ability to engage and disengage the clutch manually allows for more deliberate starts, smoother transitions, and improved overall driving experience. The 3DME clutch is a valuable upgrade for those seeking enhanced control, responsiveness, and performance from their Predator 212 engine.

Installation Process

Installing a manual clutch on your Predator 212 engine is a straightforward process that can be completed with basic tools and a little mechanical knowledge. Here’s a step-by-step guide to help you through the installation⁚

Step 1⁚ Preparation

Gather the necessary tools, including wrenches, screwdrivers, and a torque wrench. Ensure you have a clean and well-lit workspace to minimize the risk of errors. Consult your manual clutch kit instructions for specific tools and requirements.

Step 2⁚ Removing the Centrifugal Clutch

Begin by removing the centrifugal clutch from your Predator 212 engine. This typically involves loosening the nuts or bolts securing the clutch to the engine shaft. Refer to your engine’s manual or the manual clutch kit instructions for specific removal procedures.

Step 3⁚ Installing the Manual Clutch

With the centrifugal clutch removed, carefully align and install the new manual clutch onto the engine shaft. Secure it using the provided nuts or bolts, ensuring proper alignment and tightness. Double-check that the clutch is properly installed and secured before proceeding to the next step.

Step 1⁚ Preparation

Before embarking on the manual clutch installation, it’s crucial to ensure you have everything you need at hand. This step involves gathering the necessary tools, materials, and resources to make the process smooth and efficient; Start by carefully reviewing the manual clutch kit instructions, as it will outline the specific tools required for your particular kit.

Here’s a list of commonly needed tools⁚

- Wrenches⁚ These will be essential for loosening and tightening nuts and bolts during the installation process. Ensure you have the correct sizes for your engine and clutch.

- Screwdrivers⁚ You’ll need various sizes of screwdrivers for removing and securing screws, depending on the design of your manual clutch and engine mounting.

- Torque Wrench⁚ This specialized tool is vital for ensuring bolts are tightened to the correct specifications, preventing over-tightening and potential damage.

Beyond the tools, make sure you have a clean and well-lit workspace. This will minimize the risk of losing small parts and help you see clearly during the installation. It’s also a good idea to have a container for collecting the removed hardware.

Step 2⁚ Removing the Centrifugal Clutch

The first step in installing a manual clutch is to remove the existing centrifugal clutch. This process involves carefully disconnecting the clutch from the engine and the drive system, ensuring you don’t damage any components. Begin by disconnecting the spark plug wire to prevent accidental engine start-up. Next, identify the clutch mounting bolts, which are typically located around the outer edge of the clutch assembly. These bolts secure the clutch to the engine’s output shaft.

Using your wrenches, carefully loosen the mounting bolts. Be mindful of the torque specifications provided in your manual clutch kit instructions, as over-tightening can damage the engine or clutch components. Once the bolts are loosened, gently remove them from the clutch assembly. It’s recommended to keep track of the removed hardware in a designated container to avoid losing any parts.

With the mounting bolts removed, the centrifugal clutch can be carefully lifted off the engine output shaft. Pay attention to the clutch alignment and any potential interference with the engine case or other components. Once the clutch is removed, inspect it for any signs of wear or damage. This step ensures proper operation and prevents potential issues with the new manual clutch.

Step 3⁚ Installing the Manual Clutch

Now that the centrifugal clutch is removed, you can begin installing the manual clutch. The installation process typically involves aligning the new clutch with the engine output shaft and securing it with the provided mounting bolts. Ensure the clutch is properly positioned, with the input shaft aligned with the engine’s output shaft and the output shaft aligned with the drive system.

Carefully slide the manual clutch onto the engine output shaft. Ensure that the clutch engages smoothly and does not bind or rub against any components. Once the clutch is in place, align the mounting holes on the clutch with the corresponding holes on the engine case. Remember to refer to the installation instructions provided with your manual clutch kit for specific alignment guidelines.

Using the provided bolts, secure the manual clutch to the engine case. Tighten the bolts to the specified torque specifications. Be careful not to over-tighten the bolts, as this can damage the engine or clutch components. Once the bolts are securely fastened, you have successfully installed the manual clutch. Remember to double-check the alignment and secureness of the clutch before proceeding to the next step.

Adjusting the Clutch Cable

After installing the manual clutch, it’s crucial to adjust the clutch cable for optimal performance and smooth engagement. The clutch cable connects the clutch lever to the clutch mechanism, enabling you to control the engagement and disengagement of the clutch. Proper adjustment ensures that the clutch engages and disengages at the desired points and prevents premature wear on the clutch components.

Start by locating the adjustment mechanism on the clutch cable. This is typically a barrel adjuster or a set screw located near the clutch lever or the clutch mechanism itself. The adjustment mechanism allows you to fine-tune the cable tension. The goal is to achieve a balance between the clutch engaging smoothly and preventing excessive slippage.

With the engine off, slowly adjust the cable tension. You can test the adjustment by gently pulling the clutch lever. The lever should move smoothly, and the clutch should engage and disengage without any noticeable hesitation or binding; If the clutch engages too easily or slips excessively, adjust the cable tension accordingly until you find the sweet spot. Remember that the specific adjustment process may vary depending on the type of manual clutch and cable used. Consult the installation instructions or the manufacturer’s recommendations for detailed guidance on adjusting your specific setup.

Testing and Fine-Tuning

Once the manual clutch is installed and the cable is adjusted, it’s time to test its performance and fine-tune the setup for optimal results. Start by carefully starting the engine and engaging the clutch. Observe how the engine responds to the clutch lever. The clutch should engage smoothly and without any sudden jolts or hesitation. The engine should rev up smoothly when the clutch is disengaged and accelerate smoothly when the clutch is fully engaged.

If you notice any issues, such as excessive slippage or difficulty engaging the clutch, you may need to make further adjustments to the clutch cable. You can also experiment with different clutch settings, such as the point at which the clutch engages, to optimize performance based on your driving style and terrain.

Testing and fine-tuning should be done in a safe environment, preferably on a flat surface. Start at low speeds and gradually increase the speed as you become familiar with the clutch’s behavior. Listen for any unusual noises or vibrations coming from the clutch or engine. These could indicate problems that need to be addressed. By taking the time to test and fine-tune the manual clutch, you can ensure a smooth and reliable performance that enhances the overall driving experience.

Maintenance and Troubleshooting

Proper maintenance is crucial for ensuring the longevity and smooth operation of your Predator 212 manual clutch. Regularly inspect the clutch cable for signs of wear, fraying, or corrosion. Replace the cable if necessary, as a worn cable can affect the clutch’s engagement and disengagement. Also, periodically lubricate the clutch cable to prevent sticking and ensure smooth operation.

Pay attention to the clutch lever and its mounting points. Ensure that the lever is properly secured and that the mounting points are free from cracks or damage. A loose or damaged lever can compromise the clutch’s operation and potentially lead to safety issues. During routine maintenance, inspect the clutch itself for any signs of wear or damage. Check for excessive wear on the clutch plates, springs, or other components. Replace any worn or damaged parts promptly to prevent further damage and ensure proper operation.

Troubleshooting common problems with manual clutches can be done with a few simple steps. If the clutch slips excessively, it could be due to worn clutch plates or a faulty cable. Adjust the clutch cable to increase the engagement force. If the clutch doesn’t engage smoothly, check for any kinks, binding, or damage in the cable. Replace the cable if necessary. If the clutch makes unusual noises, inspect the clutch for worn or damaged components. Remember to always consult the manufacturer’s instructions and seek professional help if you’re unsure about any maintenance or troubleshooting steps. By following these tips, you can ensure that your manual clutch remains in optimal condition and delivers reliable performance.

Alternatives to Manual Clutches

While manual clutches offer a level of control and engagement that centrifugal clutches can’t match, they are not the only option for Predator 212 engines. For those seeking a more simplified setup, centrifugal clutches remain a popular choice. These clutches automatically engage when the engine reaches a certain RPM, eliminating the need for a clutch lever and cable. Centrifugal clutches are generally easier to install and require less maintenance, making them a suitable choice for beginners or those who prefer a simpler setup.

Another alternative to manual clutches is the torque converter. Torque converters are essentially automatic transmissions that use a fluid coupling to transfer power from the engine to the wheels. They offer smooth acceleration and effortless operation, particularly beneficial in applications where frequent shifting is required. However, torque converters are typically more expensive and complex than centrifugal clutches.

Ultimately, the choice between a manual clutch, a centrifugal clutch, or a torque converter depends on your specific needs, budget, and desired performance. Consider the type of kart or mini-bike you’re building, your experience level, and your desired level of control when deciding which clutch system is best suited for your application. Each type of clutch has its own advantages and disadvantages, so it’s important to weigh these factors carefully before making a decision.